IIn today’s tightly regulated pharmaceutical industry, ensuring quality isn’t optional—it’s essential. This is especially true for Active Pharmaceutical Ingredients (APIs) used in sensitive formulations like ophthalmic solutions. When it comes to maintaining GMP Tafluprost API quality, manufacturers must strictly adhere to Good Manufacturing Practice (GMP) standards. Those who follow GMP demonstrate their commitment to producing safe, consistent, and high-quality drug substances suitable for global markets.

In this blog, we’ll show how GMP certification directly impacts the quality of Tafluprost API, break down the essential elements of a GMP-compliant manufacturing system, and explain why Chemignition Laboratory stands out as a trusted, GMP-certified Tafluprost API manufacturer and global supplier.

What is GMP and Why Does It Matter?

Global health authorities recognize Good Manufacturing Practice (GMP) as a vital system for ensuring consistent production and quality control of pharmaceutical products. Regulatory bodies such as the U.S. FDA, European Medicines Agency (EMA), World Health Organization (WHO), and India’s CDSCO actively implement and monitor GMP guidelines. They inspect facilities, audit documentation, and enforce compliance to make sure manufacturers produce every batch of drug substances with the required levels of safety, purity, and efficacy—ultimately protecting public health.

- US FDA

- EU EMA

- WHO GMP

- Indian CDSCO GMP (Schedule M)

When applied to Tafluprost API manufacturing, GMP certification ensures:

- Accurate formulation and ingredient control

- Contaminant-free production environment

- Traceability of every batch

- Robust documentation for audits and product filings

Why Tafluprost Requires Strict GMP Control

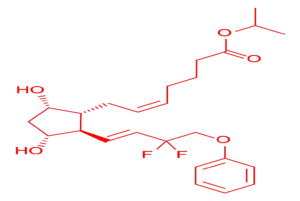

Tafluprost, a prostaglandin analog, is used in eye drop formulations to treat glaucoma and ocular hypertension. As an ophthalmic API:

- It’s used in microgram-level doses

- It must be free from particulate matter, heavy metals, and microbial contaminants

- Stability and purity are essential due to its light- and temperature-sensitive nature

- It’s applied directly to the eye, requiring the highest safety margins

Therefore, GMP compliance isn’t optional—it’s essential for both regulatory approval and patient safety.

GMP Tafluprost API quality : What It Covers by Manufacturer

At Chemignition Laboratory, our Tafluprost API is manufactured under full GMP-compliant conditions. Here’s how GMP principles translate into operational safeguards for Tafluprost quality:

1. Validated Production Processes

All manufacturing activities are governed by:

- Process validation protocols

- Standard Operating Procedures (SOPs)

- Master Manufacturing Records (MMRs)

This ensures that each batch of Tafluprost meets the exact same specifications and performance requirements.

2. Controlled Environment & Cleanroom Practices

We operate Class 100,000 (ISO 8) cleanrooms with:

- HEPA-filtered air supply

- Differential pressure monitoring

- Temperature and humidity control

- Regular microbial and particulate monitoring

This prevents cross-contamination and maintains the integrity of Tafluprost for ophthalmic use.

3. Personnel Hygiene & Training

Staff are trained in:

- GMP regulations

- Gowning procedures

- Equipment sanitization

- Documentation protocols

Only trained personnel are allowed in critical production zones, ensuring contamination control during synthesis, purification, and packaging.

4. Raw Material Quality Control

Before production begins, every raw material is tested for:

- Identity

- Assay

- Solvent residues

- Heavy metals

All suppliers undergo pre-qualification audits and regular re-assessments. Only approved vendors are used for sourcing sensitive precursors of Tafluprost.

5. In-Process Quality Checks

During manufacturing, we conduct in-process testing for:

- Reaction completion

- Purification efficiency

- Crystallization and drying

- Moisture levels

Real-time data helps ensure early detection of any quality deviation before the batch moves forward.

6. Final Product Testing

Every batch of Tafluprost API is subjected to comprehensive final testing, including:

| Test | Purpose |

|---|---|

| HPLC assay | Confirms API potency (≥ 99.0%) |

| Related substances/impurities | Ensures below pharmacopeial limits |

| Water content (Karl Fischer) | Checks for stability and moisture resistance |

| Heavy metals | Ensures safety as per ICH Q3D guidelines |

| Residual solvents | Complies with ICH Q3C guidelines |

| Microbial limits | Required for ophthalmic compatibility |

All results are recorded in a Certificate of Analysis (COA) and signed by a qualified QA chemist.

7. Stability Studies & Shelf-Life

Chemignition conducts:

- Accelerated stability testing at 40°C/75% RH

- Long-term stability testing at –20°C

Tafluprost API has a shelf life of 36 months under proper storage conditions, confirmed through real-time data.

Documentation Ensured by GMP

A core tenet of GMP is thorough documentation. Chemignition provides clients with:

- COA (Certificate of Analysis)

- MSDS (Material Safety Data Sheet)

- GMP certificate

- Stability data

- Impurity profile

- Batch manufacturing records

- Process validation data (on request)

All documentation is audit-ready and compliant with regulatory authorities across worldwide.

Global Relevance of GMP for Tafluprost Export

For pharmaceutical companies importing Tafluprost API into:

- The United States → GMP compliance is mandatory for FDA approval

- Europe → Requires a Written Confirmation (WC) stating GMP adherence

- Japan, South Korea, Brazil, South Africa → All require documented GMP manufacturing and site audits

GMP certification increases confidence for buyers, facilitates faster market entry, and minimizes the risk of product recalls or regulatory action.

Explore a leading manufacturer of APIs.

With over 10 years of expertise, we ensure GMP compliance and provide reliable, high-quality solutions.

Why Chemignition Laboratory is a Trusted GMP Tafluprost Supplier

| GMP Element | Chemignition Advantage |

|---|---|

| GMP-Certified Facilities | Verified by Indian authorities and third parties |

| In-House QA/QC Labs | Advanced equipment for real-time and final testing |

| Trained Regulatory Team | Supports GMP compliance |

| Export to 30+ Countries | With compliance packages and stability data |

| Cold-Chain Packaging & Shipment | Protects Tafluprost during transport |

| Batch Consistency | Validated processes and strict in-process checks |

GMP-Compliant Packaging & Storage for Tafluprost API

GMP also applies to post-manufacturing operations. Our Tafluprost API is:

- Packaged in triple-laminated aluminum foil bags

- Stored in temperature-controlled units (–20°C to –10°C)

- Shipped with validated cold chain logistics and data loggers

Our quality assurance team inspects every shipment to meet EU and US import regulations.

Conclusion: GMP Certification is the Foundation of API Trust

When it comes to Tafluprost API for ophthalmic use, GMP certification is not just a regulatory checkbox—it is a seal of trust, consistency, and patient safety.

With Chemignition Laboratory, you’re choosing a partner who:

- Maintains strict GMP manufacturing protocols

- Offers global compliance documentation

- Delivers quality Tafluprost API with every batch

Contact Chemignition Laboratory today for GMP-Certified Tafluprost API

Whether you need Tafluprost API for clinical trials or commercial manufacturing, Chemignition is ready to support you with:

Samples

Batch COAs

Stability data

Regulatory documentation

Global shipping

Website: www.chemignition.com

Export Markets: Worldwide

FAQs

What is GMP certification in pharmaceutical manufacturing?

GMP (Good Manufacturing Practice) certification confirms that a pharmaceutical manufacturer follows standardized procedures to ensure the consistent quality, safety, and efficacy of drug substances, including APIs like Tafluprost.

Why is GMP important for Tafluprost API quality?

Tafluprost API is used in ophthalmic formulations, which require high purity and stability. GMP certification ensures that the API is manufactured in a controlled environment, minimizing contamination and quality variation.

How does Chemignition ensure GMP Tafluprost API quality?

Chemignition follows GMP-compliant manufacturing processes, including validated procedures, cleanroom controls, in-process testing, and full traceability. Each batch undergoes strict quality checks before shipment.

Does Chemignition provide documentation for regulatory compliance?

Yes. Chemignition provides a complete documentation set including COA, MSDS, GMP certificate, impurity profile and stability data to meet global regulatory requirements.

Does GMP certification guarantee product safety?

GMP certification doesn’t eliminate all risks, but it significantly reduces them by enforcing robust systems, regular audits, and process controls. It builds trust in the API’s quality and consistency.

How do I request GMP-certified Tafluprost API from Chemignition?

You can contact us www.chemignition.com to request a quote, COA, sample, or regulatory documents.