Key Properties of Magnesium Trisilicate

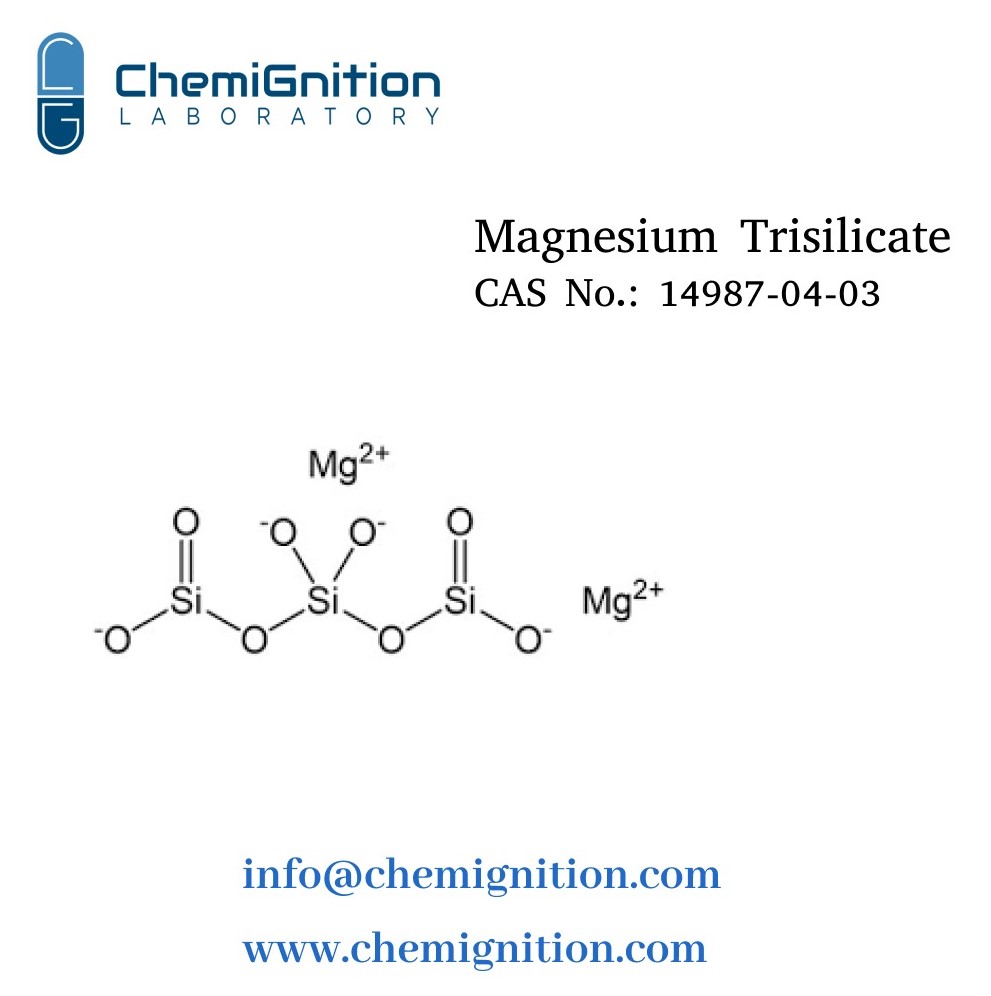

| Product Name: | Magnesium Trisilicate |

| Synonyms: | Dimagnesium;dioxido-bis[[oxido(oxo)silyl]oxy]silane |

| CAS No: | 14987-04-03 |

| Chemical Formula: | Mg₂O₈Si₃ |

| Grade: | IP/BP/USP |

| Appearance: | White, fine powder |

| Molar Mass: | 152.373 g/mol |

| Solubility: | Insoluble in water and organic solvents, Soluble in gastric acid |

| Colour: | White in colour |

| Density: | 2.83 g/cm³ |

Manufacturing process of Magnesium Trisilicate

Before beginning the process operation, ensure the cleanliness of equipment, check the availability of utilities, and verify the availability of raw materials and packing materials.

Charge sodium silicate in the reactor and adding magnesium sulfate solution under stirring. The reaction is maintained at 50–60°C to form magnesium trisilicate. After the reaction, the precipitate is filtered using vacuum filtration and washed with deionized water to remove sodium sulfate.

The product is dried in a vacuum dryer at 60–70°C for 480–600 minutes. The dried product is milled to achieve uniform particle size and sieved through the specified mesh size.

Pack Magnesium Trisilicate in a clear poly bag and twist the mouth of the bag. Secure it with a PVC strip. Place this bag inside another poly bag, twist its mouth, and secure it with a PVC strip. Finally, place the sealed bag in an HDPE container. Store Magnesium Trisilicate in a tightly closed, light-resistant container at a temperature below 30°C.

Applications of Magnesium Trisilicate

Technical Specifications of Magnesium Trisilicate

| Sr.No. | Test | Specification |

|---|---|---|

| 1 | Description | White, odorless, tasteless powder |

| 2 | Identification | A) Mix about 500 mg with 10 mL of 3 N hydrochloric acid, filter, and neutralize the filtrate to litmus paper with 6 N ammonium hydroxide: the neutralized filtrate responds to the tests for Magnesium. B) Prepare a bead by fusing a few crystals of sodium ammonium phosphate on a platinum loop in the flame of a Bunsen burner. Place the hot, transparent bead in contact with Magnesium Trisilicate, and again fuse: silica floats about in the bead, producing, upon cooling, an opaque bead with a web-like structure. |

| 3 | Water Content | 17.0% to 34.0% |

| 4 | Soluble Salts | Not more than 1.5% |

| 5 | Chloride | Not more than 0.055% |

| 6 | Sulfate | Not more than 0.5% |

| 7 | Free Alkali | Not more than 1.0 mL of 0.10 N hydrochloric acid is required to discharge the pink color of phenolphthalein TS in 20 mL of the diluted filtrate prepared in the test for Soluble salts. |

| 8 | Arsenic | Not more than 8 ppm |

| 9 | Heavy Metals | Not more than 0.003% |

| 10 | Acid-Consuming Capacity | One gram consumes not less than 140 mL and not more than 160 mL of 0.10 N hydrochloric acid |

| 11 | Assay for Magnesium Oxide (MgO) | Not less than 20.0% |

| 12 | Assay for Silicon Dioxide (SiO₂) | Not less than 45.0% |

| 13 | Ratio of SiO₂ to MgO | Between 2.10 and 2.37 |

Packing and Storage condition of Magnesium Trisilicate

Pack Magnesium Trisilicate in a clear poly bag and twist the mouth of the bag. Secure it with a PVC strip. Place this bag inside another poly bag, twist its mouth, and secure it with a PVC strip. Finally, place the sealed bag in an HDPE container. Store Magnesium Trisilicate in a tightly closed, light-resistant container at a temperature below 30°C.

Why Choose Chemignition for

Magnesium Trisilicate Supply?

Quality Assurance

Grade Compliance

Magnesium Trisilicate is manufactured in adherence to stringent global pharmaceutical standards.

In-House Quality Control

Each batch undergoes rigorous testing for purity, stability, and efficacy.

Regulatory Approvals

Certified for export and compliant with international regulatory requirements.

Large-Scale Manufacturing and Export

Grade Compliance

Magnesium Trisilicate is manufactured in adherence to stringent global pharmaceutical standards.

In-House Quality Control

Each batch undergoes rigorous testing for purity, stability, and efficacy.

Regulatory Approvals

Certified for export and compliant with international regulatory requirements.