Key Properties of Glucosamine sulfate potassium chloride

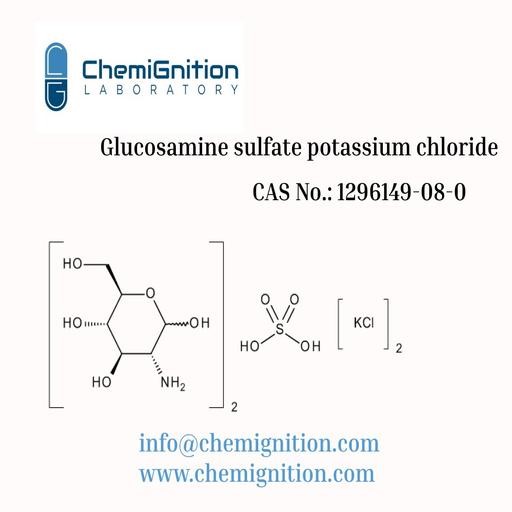

| Product Name: | Glucosamine sulfate potassium chloride |

| Synonyms: | Potassium (2R,3R,4S,5R)-2-amino-3,4,5,6-tetrahydroxyhexanal sulfuric acid chloride |

| CAS No: | 1296149-08-0 |

| Chemical Formula: | C6H15ClKNO9S |

| Grade: | USP |

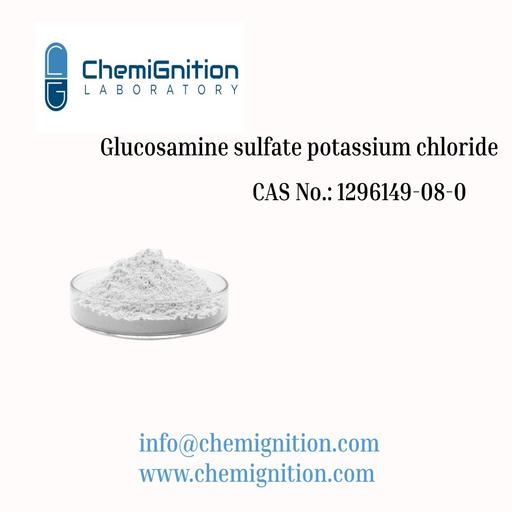

| Appearance: | White to off-white crystalline powder |

| Molar Mass: | 605.52 g/mol |

| Solubility: | Freely soluble in water, slightly soluble in ethanol, practically insoluble in organic solvents |

Manufacturing process of Glucosamine sulfate potassium chloride

1. Raw Material Selection and Preparation

The manufacturing process begins with the selection of high-quality chitin, primarily derived from shellfish shells such as shrimp and crab. This chitin undergoes deacetylation, a chemical reaction that converts it into glucosamine, the fundamental building block of the final product. The extracted glucosamine is then purified to remove impurities and ensure a high level of purity and consistency for pharmaceutical and nutraceutical applications.

2. Sulfation and Potassium Chloride Addition

Once glucosamine is obtained, it undergoes a sulfation reaction, where sulfuric acid or another sulfating agent is introduced to produce glucosamine sulfate. This step enhances the compound’s water solubility and bioavailability, making it more effective in medical applications. To stabilize the final product, potassium chloride (KCl) is added, ensuring the formation of glucosamine sulfate potassium chloride, which prevents degradation and improves shelf stability.

3. Filtration, Purification, and Drying

The resulting solution undergoes multiple filtration and purification steps to remove by-products and residual reactants. Advanced filtration and crystallization techniques help achieve a highly pure and stable compound. After purification, the solution is dried using spray drying or vacuum drying methods, converting it into a fine, free-flowing powder suitable for pharmaceutical and nutraceutical formulations.

4. Quality Control, Packaging, and Storage

The final product is subjected to strict quality control measures to ensure it meets GMP and ISO standards. Analytical techniques such as HPLC (High-Performance Liquid Chromatography) and FTIR (Fourier Transform Infrared Spectroscopy) are used to verify purity, composition, and compliance with industry regulations. The finished Glucosamine Sulfate Potassium Chloride powder is then packaged in airtight, moisture-resistant containers to maintain stability. It is stored in a cool, dry environment to prevent degradation, ensuring a long shelf life and maximum efficacy for end users.

Applications of Glucosamine sulfate potassium chloride

Technical Specifications of Glucosamine sulfate potassium chloride

| Sr.No. | Test | Specification |

|---|---|---|

| 1 | Description | White crystalline powder |

| 2 | Solubility | Freely soluble in water; slightly soluble in ethanol; practically insoluble in organic solvents |

| 3 | Identification | |

| By IR | The IR absorption spectrum of the sample must match the IR spectrum obtained from the USP reference standard. | |

| 4 | pH (2% solution) | 3.0 – 5.0 |

| 5 | Loss on drying | Not more than 1.0% w/w |

| 6 | Residue on ignition | 27.0% – 29.0% w/w |

| 7 | Heavy metals | Not more than 10 ppm |

| 8 | Assay by HPLC | |

| Glucosamine Sulfate | 98.0% – 102.0% | |

| Potassium Chloride content | 16.0% – 20.0% | |

| 9 | Microbial limits | Complies with USP standards |

Packing and Storage condition of Glucosamine sulfate potassium chloride

Pack Glucosamine sulfate potassium chloride in a clear poly bag under and twist the mouth of the bag. Secure it with a PVC strip. Place this bag inside another poly bag, twist its mouth, and secure it with a PVC strip. Insert these bags into a triple-laminated aluminum bag and sealed with a heat seal machine. Finally, place the sealed aluminum bag in an HDPE container. Store Glucosamine sulfate potassium chloride in a tightly closed, light-resistant container at a temperature below 30°C.

MSDS - Glucosamine sulfate potassium chloride

Why Choose Chemignition for

Glucosamine sulfate potassium chloride Supply?

Quality Assurance

Grade Compliance

Glucosamine sulfate potassium chloride is manufactured in adherence to stringent global pharmaceutical standards.

In-House Quality Control

Each batch undergoes rigorous testing for purity, stability, and efficacy.

Regulatory Approvals

Certified for export and compliant with international regulatory requirements.

Large-Scale Manufacturing and Export

Grade Compliance

Glucosamine sulfate potassium chloride is manufactured in adherence to stringent global pharmaceutical standards.

In-House Quality Control

Each batch undergoes rigorous testing for purity, stability, and efficacy.

Regulatory Approvals

Certified for export and compliant with international regulatory requirements.