In the pharmaceutical industry, selecting a reliable API manufacturer is a critical decision that can significantly impact the quality, safety, and success of a pharmaceutical product. Whether you’re a start-up, a growing biotech firm, or an established pharmaceutical company, finding the right API partner is key. Here’s a comprehensive guide to help you navigate this process and ensure that you partner with a trustworthy API manufacturer.

The Importance of Regulatory Compliance in API Manufacturing

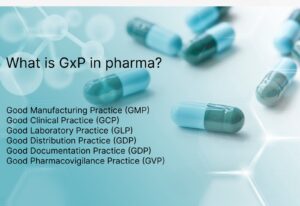

The first step in determining a reliable API manufacturer is checking their compliance with international regulatory standards. A reputable manufacturer should be certified by respected regulatory agencies, such as:

- Good Manufacturing Practice (GMP): Ensure that the manufacturer follows GMP guidelines to maintain high-quality standards in the production process.

- FDA Approval (if applicable): For products sold in the U.S., the manufacturer should be FDA-approved and capable of providing documentation for audits and inspections.

- ISO Certifications: ISO 9001 or other relevant certifications can indicate a commitment to quality management systems.

Manufacturers adhering to these standards prioritize quality, safety, and efficacy, which are essential for any pharmaceutical product’s success.

Explore a leading manufacturer of APIs.

With over 10 years of expertise, we ensure GMP compliance and provide reliable, high-quality solutions.

Evaluating the Reputation of API Suppliers in the Market

Before selecting an API supplier, it’s crucial to research the company’s market reputation. Consider the following factors:

- Client Reviews and Testimonials: Feedback from other pharmaceutical companies or industry professionals can provide valuable insight into the manufacturer’s reliability.

- Longevity in the Industry: A manufacturer with several years or decades of experience is more likely to have established solid production practices and quality assurance protocols.

- Partnerships with Reputable Clients: A manufacturer that has partnered with reputable pharmaceutical companies or works with well-known brands is often a sign of reliability.

A company’s transparency in sharing its history, credentials, and business collaborations will also give you more confidence in its abilities.

The Role of Quality Control in Reliable API Manufacturing

A strong focus on quality control is a hallmark of a reliable API manufacturer. Therefore, it’s essential to evaluate the following aspects:

- In-House and Third-Party Testing: The manufacturer should conduct rigorous in-house testing to ensure product quality. Furthermore, third-party testing adds an extra layer of assurance and transparency.

- Documented Quality Control Processes: Request detailed documentation on their quality control procedures, such as batch records, process validation reports, SOPs, and Certificates of Analysis (CoA).

- History of Recalls or Compliance Issues: Investigate whether the manufacturer has faced any product recalls or compliance issues in the past.

The manufacturer should also provide robust documentation for regulatory submissions, including comprehensive data on batch stability, impurities, and process validation.

Assessing Technological Capabilities of Your API Manufacturer

Technology plays a significant role in the production of high-quality APIs. Thus, investigate the manufacturer’s infrastructure:

- Manufacturing Capacity and Scalability: Ensure that the manufacturer can meet both your current needs and future growth, with the ability to scale up production when required.

- Advanced Equipment and Production Processes: The use of modern technologies like continuous manufacturing, advanced filtration systems, and automation are indicators of a forward-thinking manufacturer.

- Research and Development (R&D) Expertise: A manufacturer with strong R&D expertise can help optimize formulations, develop novel APIs, or adapt existing processes.

The right technological tools and infrastructure allow for consistent, high-quality production and process innovation.

Ensuring Transparent and Fair Pricing in API Manufacturing

Price is always a factor, but balancing cost with quality is key. When comparing pricing models, look for transparency and fairness:

- Detailed Cost Breakdown: A reliable manufacturer should provide a clear and detailed cost breakdown.

- Competitive Pricing Models: Be cautious of manufacturers offering extremely low prices, which could indicate compromised quality.

The right manufacturer will offer transparency in pricing, without hidden fees or last-minute surprises.

The Importance of Customer Support and Communication in API Partnerships

A reliable API manufacturer will prioritize clear and consistent communication. Therefore, evaluate their customer support and relationship management:

- Responsiveness to Inquiries: Do they respond to queries and concerns promptly? Delayed communication can cause production bottlenecks.

- Technical Assistance Availability: Are they willing to provide technical assistance or collaborate on solving issues related to product development or manufacturing?

- Potential for Long-Term Relationships: Building a long-term partnership requires trust and consistent communication.

Excellent customer support can help ensure a smoother production process and quicker problem resolution.

Supply Chain Security: A Key Factor in API Reliability

The reliability of an API manufacturer is closely tied to the robustness of their supply chain. Thus, investigate their supply chain management to ensure:

- Reputable Raw Material Sourcing: Ensure the manufacturer sources raw materials from reputable suppliers with strong traceability processes.

- Effective Inventory Management Systems: Effective inventory management systems help prevent delays or stock shortages.

- Logistics and Distribution Procedures: Ask about their shipping procedures to ensure timely and safe API delivery.

A secure supply chain ensures consistent API availability, reducing the risk of production delays.

Conducting an On-Site Audit of Your Potential API Manufacturer

If you’re seriously considering partnering with an API manufacturer, request an on-site audit. This can help you:

- Observe API Manufacturing Processes: See firsthand how the manufacturer operates and adheres to standards.

- Assess Hygiene and Safety Standards: Ensure the facility is well-maintained with proper hygiene and safety protocols.

- Engage with the Production Team: Engaging with the production and quality control teams can build your confidence in their competence.

Many manufacturers welcome audits, offering an opportunity to showcase their strengths and reinforce trust.

Conclusion

Finding a reliable API manufacturer is crucial for the success of your pharmaceutical products. By carefully evaluating regulatory compliance, reputation, quality control processes, technological capabilities, and customer support, you can select a partner that ensures the quality, safety, and success of your products. At Chemignition Laboratory, we pride ourselves on exceeding these expectations. With decades of experience in API manufacturing, cutting-edge technology, and a commitment to quality and compliance, we ensure that our clients receive the best products and services. Contact us today to discuss your pharmaceutical needs, and let us be your trusted API partner.

Chemignition Laboratory is a globally trusted manufacturer and exporter of high-quality Active Pharmaceutical Ingredients (APIs).

We specialize in APIs and provide complete documentation support including,

- GMP Certificate

- ISO 9001 Certificate

- COA

- MSDS

- Stability Data

- Impurity Profile

- Customized packaging

- Cold chain logistics

- Safe delivery of sensitive APIs

We proudly supply high-quality Active Pharmaceutical Ingredients (APIs) to pharmaceutical companies around the world.

Partner with Chemignition Laboratory for consistent quality, regulatory compliance, and reliable global delivery.

Contact us at www.chemignition.com

FAQs

What certifications should a reliable API manufacturer have?

A reliable API manufacturer should have certifications such as Good Manufacturing Practice (GMP), FDA approval (if applicable for the market), and ISO certifications like ISO 9001, which demonstrate adherence to international quality and safety standards.

How can I evaluate the reputation of an API supplier?

You can evaluate an API supplier’s reputation by reviewing client testimonials, checking their longevity in the industry, and examining partnerships with reputable pharmaceutical companies.

Why is quality control critical in API manufacturing?

Quality control ensures that the APIs meet safety, efficacy, and regulatory standards. This includes rigorous in-house and third-party testing, as well as providing detailed documentation like Certificates of Analysis (CoA) and process validation reports.

What technological capabilities should I look for in an API manufacturer?

Look for manufacturers with advanced equipment, scalable production capacity, and robust R&D expertise. Technologies like continuous manufacturing, automation, and advanced filtration systems are signs of a forward-thinking manufacturer.

What role does supply chain security play in API manufacturing?

A secure supply chain ensures consistent API availability by relying on reputable raw material sources, effective inventory management, and reliable logistics for on-time delivery.

Why is conducting an on-site audit of an API manufacturer important?

An on-site audit allows you to observe manufacturing processes, assess hygiene and safety standards, and engage directly with the production and quality teams. This provides a firsthand evaluation of the manufacturer’s capabilities and reliability.