Contamination is a major concern in industries like pharmaceuticals, biotechnology, healthcare, and food production. The presence of unwanted substances can affect product quality, safety, and compliance with industry regulations. This guide explains contamination, its different types, real-world examples, and how to control it.

What is Contamination?

Contamination is the presence of any unwanted substance in a material, product, or environment. It can come from various sources, including people, equipment, raw materials, and the surrounding environment.

For example, in pharmaceutical manufacturing, a batch of injectable drugs contaminated with bacteria can cause serious health risks. Controlling contamination is essential to ensure product safety and quality.

Types of Contamination with Examples

Contamination is classified based on its source and nature. Here are the major types:

1. Physical Contamination

Definition: Presence of foreign objects like dust, hair, fibers, glass, plastic, or metal in a product.

Example:

- In the food industry, a piece of metal from processing equipment accidentally falling into packaged food can cause injury to consumers.

- In pharmaceuticals, glass shards from broken vials contaminating a drug solution can pose serious health hazards.

2. Chemical Contamination

Definition: Introduction of unwanted chemical substances such as cleaning agents, pesticides, or industrial residues into a product.

Example:

- A pesticide residue found in a batch of herbal medicine can lead to product recalls.

- Traces of cleaning solvents remaining in pharmaceutical manufacturing equipment can contaminate the next product batch.

3. Microbial Contamination

Definition: Contamination caused by microorganisms like bacteria, fungi, yeast, or mold. This is one of the most dangerous forms of contamination, especially in sterile environments.

Example:

- In hospitals, bacterial contamination in surgical instruments can lead to infections in patients.

- In pharmaceuticals, fungal contamination in an injectable drug can cause severe infections in immunocompromised patients.

4. Cross-Contamination

Definition: Contamination of a product with another substance or product due to shared equipment, improper cleaning, or airborne particles.

Example:

- In a bakery, peanut residue from one batch contaminating a nut-free product can trigger allergic reactions in consumers.

- In a pharmaceutical plant, active ingredients from one drug contaminating another due to inadequate cleaning between production runs.

5. Endotoxin Contamination

Definition: Contamination with endotoxins, which are toxins released by certain bacteria, mainly Gram-negative bacteria. These are harmful, especially in injectable drugs.

Example:

- In sterile drug manufacturing, endotoxins in an injectable vaccine can cause fever, shock, or other severe reactions in patients.

6. Particulate Contamination

Definition: Presence of unwanted microscopic particles such as dust, fibers, or metal shavings that can affect the safety and quality of the final product.

Example:

- In semiconductor manufacturing, tiny dust particles on silicon wafers can lead to defects in electronic chips.

- In pharmaceuticals, particulate contamination in an eye drop solution can cause irritation and infection in patients.

Explore a leading manufacturer of APIs.

With over 10 years of expertise, we ensure GMP compliance and provide reliable, high-quality solutions.

Sources of Contamination

Contamination can come from various sources. Understanding these helps in implementing effective control measures.

| Source | Potential Contaminants | Examples |

|---|---|---|

| Personnel | Skin flakes, hair, sweat, respiratory droplets | Workers not wearing masks shedding microbes onto sterile surfaces |

| Equipment | Metal shavings, lubricants, cleaning agent residues | Poorly maintained machinery shedding particles |

| Air | Dust, pollen, microbial spores | Ineffective air filtration allowing contaminants to enter |

| Raw Materials | Microbial growth, chemical residues, foreign objects | Contaminated raw ingredients introducing bacteria |

| Water | Microbes, endotoxins, heavy metals | Improperly treated water causing microbial growth in drug production |

How to Prevent Contamination?

Industries use strict control strategies to prevent contamination and ensure product safety.

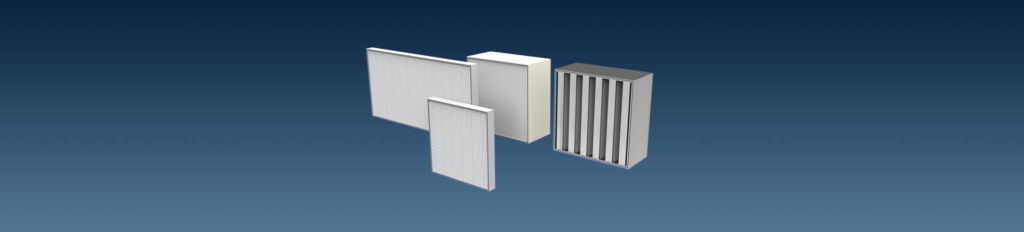

1. Facility Design and Air Control

- Use HEPA and ULPA filters to remove tiny airborne particles.

- Maintain positive air pressure to keep contaminants out.

- Implement laminar airflow in critical areas to reduce particle buildup.

- Regularly monitor air change rates to ensure optimal cleanliness.

2. Personnel Hygiene and Protocols

- Follow strict gowning procedures (gloves, masks, sterile suits).

- Enforce hand washing and sanitization before entering cleanrooms.

- Train staff to minimize movement and avoid unnecessary talking inside clean environments.

3. Equipment and Material Handling

- Regularly clean and disinfect machinery and tools.

- Implement material transfer protocols to prevent cross-contamination.

- Store raw materials in sealed and labeled containers to prevent mix-ups.

4. Environmental Monitoring

- Use particle counters to track airborne contamination.

- Conduct microbial testing using swabs and settling plates.

- Implement real-time monitoring systems for early contamination detection.

5. Waste Management and Cleaning

- Dispose of waste materials properly (e.g., gloves, wipes, disposable gowns).

- Follow strict cleaning schedules using approved disinfectants.

- Prevent contamination spread by separating waste disposal zones from production areas.

The Role of Human Discipline in Contamination Control

Even with the best technology, human discipline is key to preventing contamination. Employees must:

- Follow SOPs (Standard Operating Procedures) to maintain a clean and safe environment.

- Practice good hygiene, including wearing protective gear.

- Adhere to cleaning protocols to prevent cross-contamination.

- Be aware of contamination risks and report any potential issues.

- Undergo regular training to stay updated on best practices.

By following strict procedures and staying vigilant, industries can significantly reduce contamination risks.

Conclusion

Contamination is a serious issue that can affect product safety, compliance, and consumer health. Different types of contamination—physical, chemical, microbial, cross-contamination, endotoxin, and particulate—require specific control strategies. Industries must implement facility design improvements, strict hygiene protocols, advanced monitoring, and proper waste management to prevent contamination. Most importantly, human discipline and adherence to protocols play a critical role in maintaining contamination-free environments.

By understanding contamination sources and applying best practices, businesses can ensure product integrity, protect consumers, and meet regulatory requirements.

FAQs

What is the most common source of contamination in cleanrooms?

Human personnel are the biggest contamination source due to skin flakes, hair, respiratory droplets, and movement inside the cleanroom.

How do HEPA filters help in contamination control?

HEPA filters remove 99.97% of airborne particles as small as 0.3 microns, keeping cleanrooms free from dust and microorganisms.

What is the difference between contamination and cross-contamination?

Contamination refers to any unwanted substance in a product, while cross-contamination occurs when one product gets contaminated by another due to shared equipment or improper cleaning.

How can endotoxin contamination be prevented?

Use sterile water, proper filtration, and regular testing to detect and eliminate endotoxins in injectable drugs.

Why is environmental monitoring important in contamination control?

It helps detect airborne particles and microbial growth before they compromise product quality, ensuring compliance with industry standards.